Construction equipment, pumps, meters, and tools need to show relevant specs and tolerances in a way that is easy to understand. It is imperative for these pieces of information to remain legible for the duration of the equipment's use cycle - which is why McLoone provides durable ID plates for industrial applications.

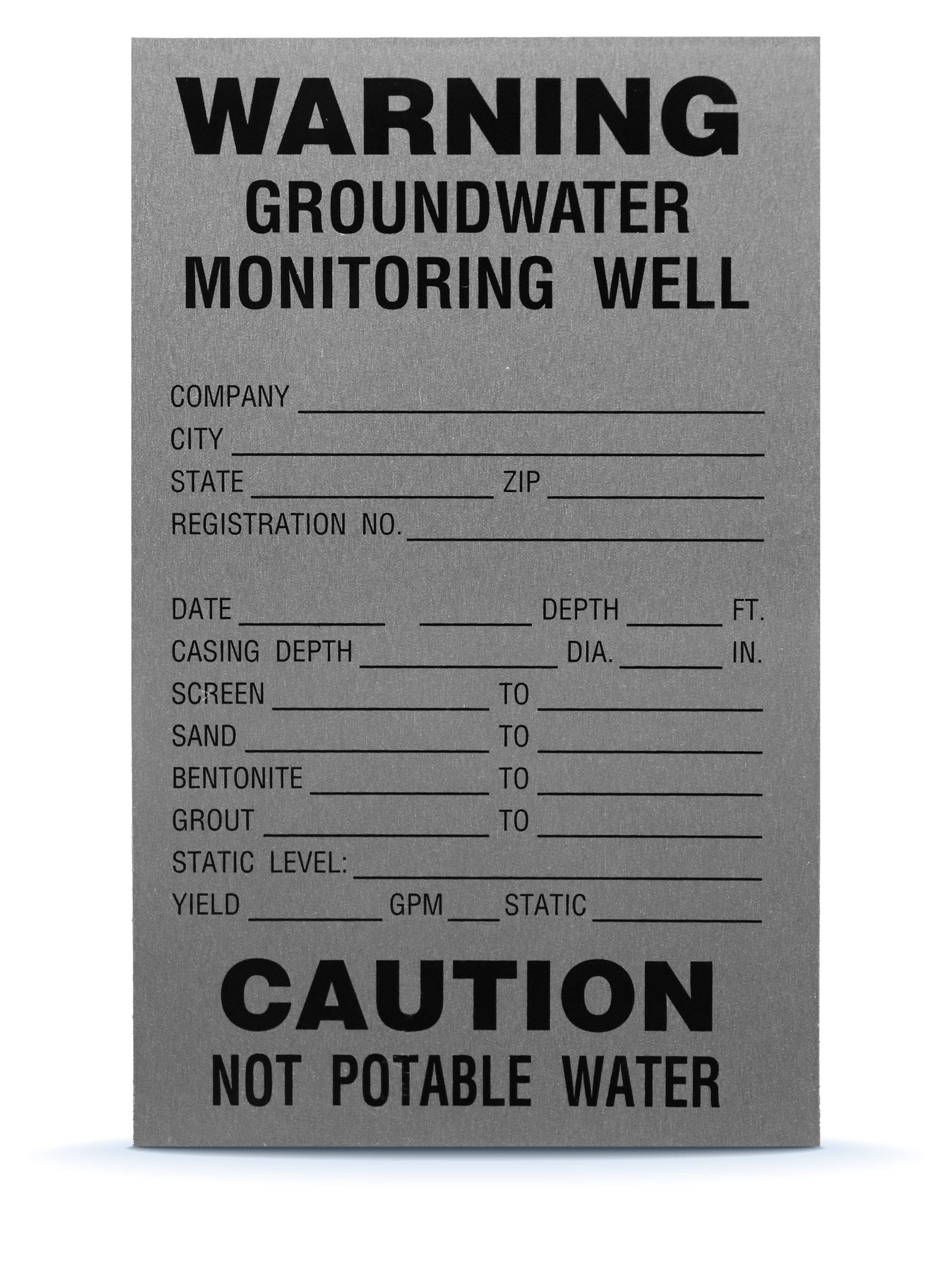

ID plates are used on tools and equipment to communicate critical information like proper use, safety measures, and equipment maintenance for companies in every industry. Model plates and serial plates are just a couple of ID plates that provide operators with a visual reference for parameters like voltage, pressure, temperature ratings, and more crucial information.

It is vital for users to quickly recognize safe operating instructions for industrial equipment to reduce working hazards. Improperly labeled equipment may cause a failure which could be otherwise avoided with an effective ID plate. Preventable failures like these can lead to poor machine performance, costly damage to machinery and tooling, and potential injury to workers or consumers. As part of the Clarion Safety Systems family, we are able to provide best practice safety labels and signage, along with complementary risk-reduction services through their affiliated businesses: Machine Safety Specialists and Arrow Industrial Solutions.

When done right, ID plates should have clean, simple, and easy to read designs to communicate important information that may prevent improper use. The construction of an ID plate should facilitate long-lasting performance to maintain readability, even when used on equipment that operates in the harshest of environments.

Many industrial environments have equipment that is exposed to harsh working conditions like chemical exposure, extreme temperatures, weather conditions, heavy handling, and pollutants. Choosing the right processing and materials for ID plates ensures that key safety and use information will always be visible to operators by minimizing the risk of wear over time. We stock a variety of metal and flexible substrate options to provide the right protection, functionality, and durability for your application along with the custom decoration needed for your design.

In applications where a piece of equipment will be subjected to harsh conditions like physical abrasives, a metal ID plate may be a suitable way to convey information. Our most popular metal ID plate options include the following:

Aluminum ID plates display excellent chemical resistance and durability, making them a great choice for industrial applications.

Stainless steel ID plates are better suited to outdoor use, thanks to their corrosion resistance.

For a closer look at the specs for each substrate, please see the table below:

Material |

Thickness and Finish |

|

Aluminum

|

.002" Matte and Bright Foil .012"-.032" Mill Finish and Bright .012"-.063" Anodized .062"-.090" Mill Finish |

|

Stainless Steel

|

.018"-.036" Brushed |

|

Polycarbonate

|

.005"-.030" Clear, Velvet, Weatherable |

|

Polyester

|

.002" White, Clear, Matte Silver, Brushed Silver, Bright Silver, Imprintable, Reflective .005"-.010" Clear |

|

Vinyl

|

.002"-.004" Standard .007" Static Cling .010"-.065" Rigid |

Each ID plate application is different, and some cases require a creative solution. McLoone has the design expertise and years of experience to determine the best substrate we can offer for your ID plate needs.

To be effective, an ID plate needs to be easy to read and understand. An ID plate that is too complicated or hard to read can get in the way of what you want to communicate.

When designing an ID plate, remember your objective and what you want users to learn from the plate. Whether the goal of the equipment tag is asset tracking or communicating safety information, every design element should support this goal. We’ve compiled a quick checklist with 6 simple tips for effective ID plate design, which is available at the link below.

Need help designing an effective ID Plate? We've got you covered! From custom tools built in-house to graphic layout assistance, McLoone will work with you every step of the way to craft an ID plate that is durable and easy to understand.

Aluminum and stainless steel are offered as strong and durable material for industrial ID plates. For applications requiring flexible substrates, a variety of plastic materials are also available including polyester, polycarbonate, and vinyl. Not sure of which material is right for your application? McLoone will work with you to find a solution.

Each ID plate is custom built-in size, shape, and configured with appropriate cut-outs to meet unique requirements for every application. A library with thousands of dies in common sizes means many options for your ID Plate needs. In-house tooling facilitates quick turnaround for custom ID plate builds.

Sequential numbering for ID plates is configured into the production process using printing or stamping. Further variable data can be added with laser engraving or stamping equipment by the customer at their site.

Artwork for ID plates is produced in Adobe Illustrator. If you are providing your own artwork for an ID plate, we prefer VECTOR artwork whenever possible for production purposes. See our Artwork Submission page for full details on artwork requirements for ID plates and other McLoone products.

75 Sumner Street, La Crosse, WI 54603

1-800-624-6641 info@mcloone.com